Xididada Kaaboolka dhoobada ah ee baakadaha semiconductor

Codsiga alaabta

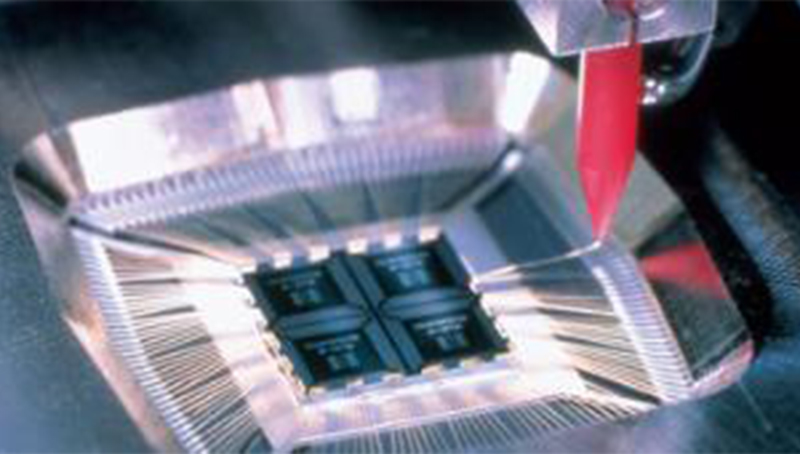

Ceramic Capillary waa qalab dhoobo axisimmetrical ah oo leh daloolo dhanka toosan ah, kaas oo iska leh qaab dhismeedka yar ee saxa ah ee qayb dhoobada ah.Marka la eego codsiga, Capillary Ceramic waxaa loo isticmaalaa sidii qalab isku xira siligga habka isku xidhka siliga.WireBonding waxay ka dhigi kartaa sunta rasaasta inay si dhow ugu xirto suufka substrate-ka iyadoo la adeegsanayo fiilooyinka birta dhuuban (naxaasta, dahabka, iwm.) iyo kulaylka, cadaadiska, iyo tamarta ultrasonic, si loo ogaado xiriirka korantada ee u dhexeeya chips iyo substrates iyo isweydaarsiga macluumaadka ee u dhexeeya chips.Ku haboon xirida iyo baakadaha SCR, SAW, LED, diode, triode, chip IC iyo wareegyada kale.

Faa'iidooyinka alaabta

OPT Cutting Tools Co., LTD.Waxay ku taal Shenzhen, Guangdong, Shiinaha.Waa shirkad isku-dhafan wax-soo-saarka, iibinta, cilmi-baarista iyo horumarinta.Oo waxay samayn kartaa naqshadaynta iyo samaynta sawir-gacmeedka, alaabta iyo qalabka aan caadiga ahayn.Si adag u qaad agabka wax soo saarka ee safka hore ee gudaha si aad u hubiso xasiloonida qaybaha kala duwan ee agabka.Si adag u xakamee habka wax soo saarka si aad u hubiso tayada qalabka.Shirkaddu waxay leedahay awood farsamo oo la taaban karo, awood wax soo saar oo xoog leh, maarayn saynis ah, iyada oo ujeedadu tahay "badbaadada tayada, horumarinta sumcadda", oo si joogto ah u sii horumarisa si ay u siiso macaamiisha alaab wanaagsan.

gaarsiin sax ah, adeeg wanaagsan

1. Qalabka Goynta OPT wuxuu leeyahay nidaam wax-soo-saar, wax-soo-saar iyo gaadiid oo dhammaystiran.Waqtiga gaarsiinta.

2. Mid hal ilaa hal isgaadhsiin iyo isdhaafsi ayaa lala samayn karaa macaamiisha si ay si fiican u siiyaan macaamiisha qalab ku habboon oo ka wanaagsan oo isku dhejinta dhoobada

3. U habayn xuduudaha gaarka ah iyadoo loo eegayo shuruudaha gaarka ah ee macaamilka;

Kordhinta Maaddada Capillary

Iyada oo ku saleysan aluminium oxide asalka ah, zirconia, chromium oxide, iwm ayaa lagu daraa si ay u sameeyaan qaab-dhismeedka molecular ee Capillary Ceramic si aad u cufan, oo leh qallafsanaan sare, xirashada caabbinta wanaagsan iyo nolosha adeegga dheer.Iska yaree xirashada iyo waqtiyada beddelka caarada dhoobada dhoobada inta lagu jiro alxanka siliga.

Xirmooyinka Xadhkaha dhuuban ee Xajmiga Xajmiga saxda ah

Shirkaddayadu waxay qabataa qalab wax-soo-saar buuxa oo la soo dejiyo si loo farsameeyo dhammaan cabbirrada astaamaha ah.Qalabka saxda ah ee saxda ah iyo waayo-aragnimada hodanka ah ee farsamaynta ayaa siiya macaamiisha alaabada cabbirka adag.

Saxnaanta sare, saxnaanta cabbir sare, mashiin yar iyo dusha siman.

Alaabtu waxay leedahay saxnaanta sare, saxnaanta cabbirka sare, qadar yar oo mashiinka iyo dusha siman.

Qaab dhismeedka Capillary Ceramic waa mid aad u sax ah oo adag, iyo cabbirkeeda muhiimka ah ayaa saameyn weyn ku leh saameynta isku-xirnaanta fiilada.Qalabka Goynta OPT ayaa si adag u koontaroolaya habka wax soo saarka si loo hubiyo tayada qalabka.Si loo gaaro saxnaanta badeecada sare, saxnaanta cabbirka sare, farsamaynta yar, iyo dusha siman.Shirkadeena waxaa ka go'an R&D iyo soo saarista aaladaha isku xirka dhoobada gudaha iyo heerka dhexe iyo sare ee goobta xirmooyinka IC.Budada dhoobada ah iyo qaybaha embriyaha ayaa si buuxda loo horumariyay oo loo soo saaray si madaxbannaan.

![]()

BPP:150μm (μm/mil)

| Qaybta NO. | WD | H | T | CD | OR | α | Θ | CA |

| A-1 | 38/1.5 | 51/2.0 | 229/9.0 | 102/4.0 | 38/1.5 | 8° | 30° | 120° |

| A-2 | 38/1.5 | 51/2.0 | 152/6.0 | 66/2.6 | 10/0.4 | 0° | 30° | 90° |

| A-3 | 38/1.5 | 51/2.0 | 229/9.0 | 86/3.4 | 102/4.0 | 0° | 30° | 90° |

| A-4 | 38/1.5 | 51/2.0 | 203/8.0 | 86/3.4 | 61/2.4 | 0° | 30° | 90′ |

| A-5 | 38/1.5 | 56/2.2 | 239/9.4 | 102/4.0 | 38/1.5 | 8° | 30° | 120° |

| A-6 | 38/1.5 | 56/2.2 | 229/9.0 | 96/3.8 | 102/4.0 | 0° | 30° | 90° |

| A-7 | 38/1.5 | 56/2.2 | 203/8.0 | 86/3.4 | 61/2.4 | 0° | 30° | 90° |

| A-8 | 38/1.5 | 64/2.5 | 239/9.4 | 102/4.0 | 38/1.5 | 6° | 30° | 120° |

| A-9 | 38/1.5 | 64/2.5 | 203/8.0 | 89/3.5 | 61/2.4 | 0° | 30° | 90° |

| A-10 | 51/2.0 | 64/2.5 | 191/7.5 | 81/3.2 | B/0.3 | 0° | 30° | 90° |

| A-11 | 51/2.0 | 64/2.5 | 292/11.5 | 102/4.0 | 127/5.0 | 0° | 30° | 90° |

| A-12 | 51/2.0 | 76/3.0 | 356/14.0 | 122/4.8 | 152/6.0 | 0° | 30° | 90° |

| A-13 | 51/2.0 | 89/3.5 | 419/16.5 | 135/5.3 | 178/7.0 | 0° | 30° | 90° |

| A-14 | 51.64/2.0.2.5 | 76/3.0 | 330/13.0 | 140/5.5 | 64/2.5 | 8° | 30° | 120° |

| A-15 | 64.76/2.5.3.0 | 89/3.5 | 330/13.0 | 127/5.0 | 64/2.5 | 8° | 30° | 120° |

| A-16 | 64.76/2.5.3.0 | 102/4.0 | 330/13.0 | 140/5.5 | 64/2.5 | 8° | 30° | 120° |

| A-17 | 76/3.0 | 102/4.0 | 483/19.0 | 168/6.6 | 203/8.0 | 0° | 30° | 90° |

BPP:140μm(μm/mil)

| Qaybta NO. | WD | H | T | CD | OR | α | Θ | CA |

| B-1 | 22/0.9 | 33/1.3 | 140/5.5 | 64/2.5 | 20/0.8 | 8° | 30° | 120° |

| B-2 | 25/1.0 | 38/1.5 | 165/6.5 | 74/2.9 | 25/1.0 | 8° | 30° | 120° |

| B-3 | 25/1.0 | 38/1.5 | 89/3.5 | 53/2.1 | B/0.3 | 0° | 30° | 90° |

| B-4 | 25/1.0 | 38/1.5 | 114/4.5 | 53/2.1 | 8/0.3 | 0° | 30° | 90° |

| B-5 | 25/1.0 | 38/1.5 | 178/7.0 | 64/2.5 | 76/3.0 | 0° | 30° | 90° |

| B-6 | 25/1.0 | 38/1.5 | 203/8.0 | 53/2.1 | 89/3.5 | 0° | 30° | 90° |

| B-7 | 25/1.0 | 43/1.7 | 165/6.5 | 74/2.9 | 25/1.0 | 8° | 30° | 120° |

| B-8 | 25/1.0 | 43/1.7 | 203/8.0 | 53/2.1 | 89/3.5 | 0° | 30° | 90° |

| B-9 | 25.30/1.0.1.2 | 43/1.7 | 229/9.0 | 74/2.9 | 30/1.2 | 8° | 30° | 120° |

| B-10 | 25.30/1.0.1.2 | 43/1.7 | 152/6.0 | 59/2.3 | B/0.3 | 8° | 30° | 120° |

| B-11 | 25.30/1.0.1.2 | 43/1.7 | 203/8.0 | 74/2.9 | 89/3.5 | 0° | 30° | 90° |

| B-12 | 25.30/1.0.1.2 | 46/1.8 | 229/9.0 | 74/2.9 | 38/1.5 | 8° | 30° | 120° |

| B-13 | 30/1.2 | 46/1.8 | 203/8.0 | 76/3.0 | 89/3.5 | 0° | 30° | 90° |

BPP: 100μm(μm/mil)

| Qaybta NO. | WD | H | T | CD | OR | α | Θ | CA |

| C-1 | 25/1.0 | 38/1.5 | 130/5.1 | 53/2.1 | 30/1.2 | 11 | 30° | 90° |

| C-2 | 30/1.2 | 38/1.5 | 130/5.1 | 56/2.2 | 30/1.2 | 11 | 30° | 90° |

| C-3 | 30/1.2 | 38/1.5 | 130/5.1 | 56/2.2 | 30/1.2 | 8′ | 30° | 90° |

| C-4 | 30/1.2 | 38/1.5 | 130/5.1 | 56/2.2 | 30/1.2 | 4′ | 30° | 90° |

| C-5 | 30/1.2 | 41/1.6 | 130/5.1 | 59/2.3 | 30/1.2 | 11 | 30° | 90° |

BPP: 90μm(μm/mil)

| Qaybta NO. | WD | H | T | CD | OR | α | Θ | CA |

| D-1 | 25/1.0 | 33/1.3 | 109/4.3 | 51/2.0 | 13/0.5 | 11° | 30° | 90° |

| D-2 | 25/1.0 | 33/1.3 | 109/4.3 | 51/2.0 | 13/0.5 | 8° | 30° | 90° |

| D-3 | 25/1.0 | 33/1.3 | 109/4.3 | 51/2.0 | 13/0.5 | 4° | 30° | 90° |

| D-4 | 25/1.0 | 35/1.4 | 109/4.3 | 51/2.0 | 20/0.8 | 11° | 30° | 90° |

| D-5 | 30/1.2 | 38/1.5 | 109/4.3 | 51/2.0 | 20/0.8 | 11° | 30° | 90° |

| D-6 | 30/1.2 | 38/1.5 | 109/4.3 | 53/2.1 | 1310.5 | 8° | 30° | 90° |

| D-7 | 30/1.2 | 38/1.5 | 109/4.3 | 53/2.1 | 13/0.5 | 4° | 30° | 90° |

BPP: 80μm(μm/mil)

| Qaybta NO. | WD | H | T | CD | OR | α | Θ | CA |

| E-1 | 25/1.0 | 33/1.3 | 99/3.9 | 48/1.9 | 13/0.5 | 4° | 30° | 90° |

| E-2 | 25/1.0 | 33/1.3 | 99/3.9 | 4B/1.9 | 13/0.5 | 8° | 30° | 90° |

| E-3 | 25/1.0 | 33/1.3 | 99/3.9 | 48/1.9 | 13/0.5 | 11° | 30° | 90° |

| E-4 | 25/1.0 | 35/1.4 | 99/3.9 | 46/1.8 | 13/0.5 | 11° | 30° | 90° |

| E-5 | 30/1.2 | 38/1.5 | 99/3.9 | 51/2.0 | 13/0.5 | 4° | 30° | 90° |

| E-6 | 30/1.2 | 3B/1.5 | 99/3.9 | 51/2.0 | 13/0.5 | 8° | 30° | 90° |

BPP: 70μm(μm/mil)

| Qaybta NO. | WD | H | T | CD | OR | α | Φ | CA |

| F-1 | 25/1.0 | 30/1.2 | 91/3.6 | 43/1.7 | 10/0.4 | 8° | 30° | 90° |

| F-2 | 25/1.0 | 30/1.2 | 91/3.6 | 43/1.7 | 10/0.4 | 4° | 30′ | 90° |

| F-3 | 25/1.0 | 33/1.3 | 91/3.6 | 43/1.7 | 13/0.5 | 11° | 30′ | 90° |

BPP: 60μm(μm/mil)

| Qaybta NO. | WD | H | T | CD | OR | α | Φ | CA |

| G-1 | 23/0.9 | 28/1.1 | 81/3.2 | 35/1.4 | 13/0.5 | 11° | 30° | 90° |

| G-2 | 25/1.0 | 30/1.2 | 81/3.2 | 35/1.4 | 13/0.5 | 11° | 30° | 90° |